ConnectedGRC

Drive a Connected GRC Program for Improved Agility, Performance, and Resilience

-

BusinessGRC

Power Business Performance and Resilience

Discover ConnectedGRC Solutions for Enterprise and Operational Resilience

Explore What Makes MetricStream the Right Choice for Our Customers

Discover How Our Collaborative Partnerships Drive Innovation and Success

- Want to become a Partner?

Find Everything You Need to Build Your GRC Journey and Thrive on Risk

Learn about our mission, vision, and core values

Automating Supply Chain Governance - HD Supply

Optimizing the efficiency and agility of a supply chain governance program

The Client: Automating Supply Chain Governance

Overview

One million SKUs of products! That's the volume of inventory that HD Supply works with. Clearly, it is not an easy task managing the vast number of suppliers and sub-suppliers associated with these products. HD Supply knew the best way to manage this was through well-defined and robust supplier governance and onboarding processes, which they had in place. However, a few years ago, these processes began growing increasingly complex. The paperwork involved in supplier selections, factory investigations, and audits had become extensive. On any given day, supply chain managers would find their inboxes inundated with emails and attachments which would quickly bog down internal systems.

Moreover, people used their own versions and templates while filling in supplier data spreadsheets. As a result, supply chain managers spent considerable time and effort searching and sifting through multiple documents, emails, and reports to find the data they needed .At the time, HD Supply was looking towards new growth opportunities, spurred by new expansion plans. This required an increasingly sharp focus on the performance and quality of their entire global supply base. In line with this, the company adopted a new streamlined, automated, and work-flowbased approach to supplier onboarding and governance

Solution

Looking Towards a New Supply Chain Governance Strategy:

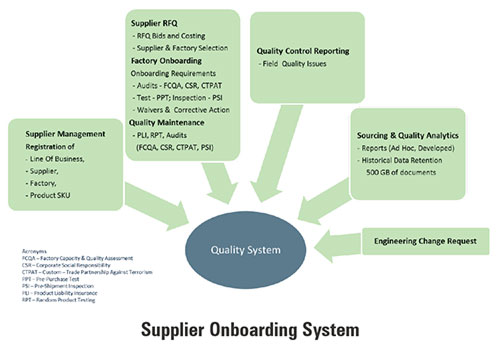

HD Supply's enhanced supply chain governance program is now able to keep pace with their overall growth and expansion strategy. Their new program also facilitates greater transparency by consolidating all supplier and product information in one centralized location. The program focuses on key areas including:

Streamlining, integrating and automating supplier governance processes:

The company implemented a workflow-based supplier governance and sourcing and quality system that offers a single point of reference to manage and track all suppliers and associated processes. Users can easily view crucial information about HD Supply's suppliers and factories, where they are located, important contact information, qualifications, and audit history. They can also automate and accelerate processes such as selecting the SKUs that need to be quoted, sending the quotes out and calculating landed costs.

Strengthening the efficiency and transparency of supplier audits and product tests:

Each time a new supplier is selected, the company conducts multiple factory assessments, including C-TPAT, quality audits, commercial risk audits, and product testing. All processes can now be planned, managed, and tracked from one centralized supplier governance system.

The company has been able to gain greater visibility into Environment, Health, and Safety (EH&S) impact assessments and have greater understanding as to which EH&S areas are important, and what needs to be done.

All data -- including audit and assessments results, product test findings, and factory pass/fail scores -- can be uploaded easily, and stored in a common repository. This enables supply chain managers to gain a bird's eye view of supply chain quality.

To further optimize supply chain visibility, especially for business stakeholders, the supply chain governance team can easily assign audit scores to each factory (e.g., A, B, C, D). The re-audit frequency is based on these scores. Therefore, an A-level factory would not have to be audited as much as a C-level factory.

Apart from internal audits and investigations, HD Supply also sends sample products for third-party lab testing, which follows the lifecycle of each product. All product testers have been trained to use the new supply chain governance system and enter their test findings into the central repository. As soon as they enter new information, supply chain managers at HD Supply are automatically alerted.

Improving tracking of regulatory certifications:

Each SKU is associated with certain regulatory certifications and standards (e.g., Department of Energy certifications, or conflict minerals reporting requirements). These requirements have been incorporated into every SKU's attributes, and then mapped to the relevant suppliers and factories. So, if a supply chain manager runs a report, he or she can quickly determine which SKUs have been certified and which ones haven't.

Enabling flexible reporting:

When it comes to reporting, users now have the flexibility to either enter data directly into the supplier governance system or into spreadsheets, depending on what they are most comfortable with. If it is the latter, the system automatically pulls data off the spreadsheet and populates the reports. Looking Towards a New Supply Chain Governance Strategy Users can also easily configure reports, add or delete columns and perform a wide range of other such customizations. For instance, they have color-coded spreadsheet rows to facilitate greater understanding of factory audit schedules. For example, the rows in red indicate which factory audits are overdue, whereas the rows in yellow indicate which audits are coming up in the next 60 days.

Simplifying governance:

Supply chain managers have gained in-depth visibility into supplier and product information and can drill down to the SKU level to view the status of a product. They can also easily track issues in supplier factories, as well as issues specific to certain geographic regions, areas where further supplier training is required, ways to strengthen factories and other crucial metrics.

Given all of these benefits, it wasn't difficult to get management buy-in and support around this new supply chain governance system. The supply chain team had done its due diligence and was able to confidently approach management with the promise that they could send one comprehensive email report per day, rather than 20 large emails.

Management and other key internal stakeholders were pleased with the level of transparency that the new system offered. If they wanted to know about the status of supplier onboarding or testing, they wouldn't have to call supply chain managers to search for the requested information. Instead, they could directly access this data on the new system wherever and whenever required.

Risk Assessment Capabilities:

The MetricStream solution allowed the Audit Management department to integrate with the Risk Management solution and supported risk assessment based on parameters such as severity and likelihood of occurrence for calculating the risk index of a finding. The solution supported computations based on configurable methodologies and algorithms giving auditors a clear view into organizations risk profile. The system allowed for customized risk and relevance criteria, risk templates, and scoring methodology to be developed at any level of the organization.

Regulatory Compliance:

The MetricStream solution supported various statistics required in 404 Assessment reports, such as number of controls by controls sets, number of controls tested in each phase, number of exceptions in each phase, number of Auto/Manual Controls by control set. The solution also provided for ‘quarterly 302 certification’, by supporting online questionnaire/surveys and making reporting tools available to consolidate and analyze questionnaire/surveys.

Easy-to-Use User Interface:

The MetricStream framework provided a rich feature set for configuring the solution according to the company’s established processes, allowing the company to tailor the solutions to business specific standards and requirements. With the MetricStream solution's user-friendly interface and drag and drop functionality, the company’s managers could get simple breakdowns and complex combinations instantaneously; document types, status, audit history, in-process documents, approval cycle times, document usage summaries, and average review times could all be obtained quickly and easily within a few drags and clicks on field data. Multiple tables or graphs could be generated giving a bird's eye preview to the risk portfolio.

Enhancing collaboration with suppliers and customers

Suppliers across the chain have been trained on how to use the new governance system. Some have adapted better than others, but both suppliers and customers now have the advantage of interfacing with HD Supply through this new system, eliminating the need to call or email the company's supply chain governance personnel to determine the status of a product or process. Now, by logging in to the system, they are able to gain real-time insight around the information they need.

The Enabling Role of Technology

To support and enable its supply chain governance strategy, HD Supply implemented MetricStream's Supply Chain Governance Solution, which provides the following capabilities:

- A centralized and streamlined approach to all supplier governance and onboarding processes - extending from supplier registration, to RFQ management, to supplier selection and onboarding, to audits and supplier quality management, to reporting

- A single, secure and easily searchable database which integrates all supply chain information including supplier audit findings and product test results

- Complete and real-time visibility into supply chain governance processes, including the status of audits and investigations

- The automation of resource-intensive workflows such as reports and alerts to personnel regarding new tasks or new information

- Standardized information templates, spreadsheets and reports MetricStream GRC

Subscribe for Latest Updates

Subscribe Now